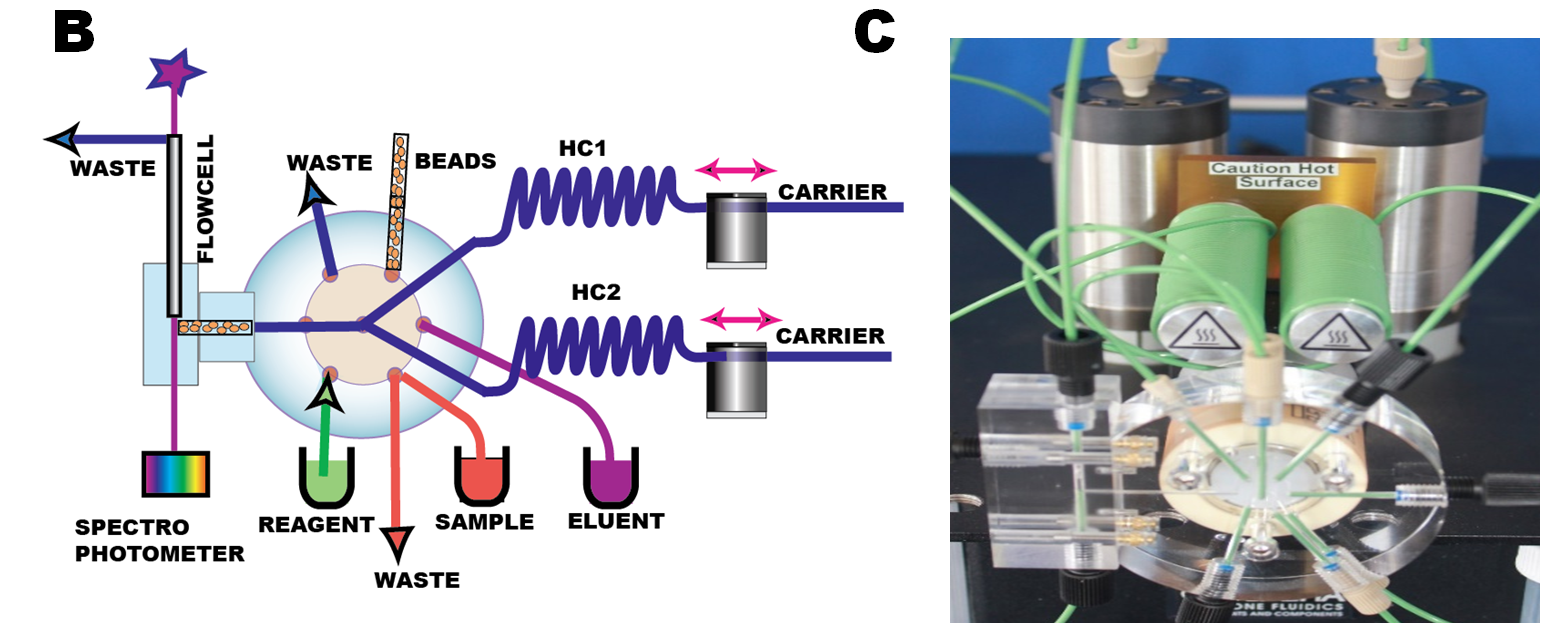

Flow programming and miniaturization of flow system are the essential components that makes BI technique feasible. Therefore it was the combination of Sequential Injection technique (Chapter 2), with lab-on-valve microfluidics that was the first platform on which bead injection instruments have been designed. However, the recent advances in micro pumping and the novel concept of programmable Flow Injection (pFI) expands the range of tools and instruments suitable for BI. pFI offers a wider range of microfluidic manipulations of which sample/reagent confluence is the most important one, because it allows to processing of sample volumes that are much larger than those handled by SI. This novel, useful feature is highlighted in this Tutorial by example of assay of traces of iron (1.3.14.B.)

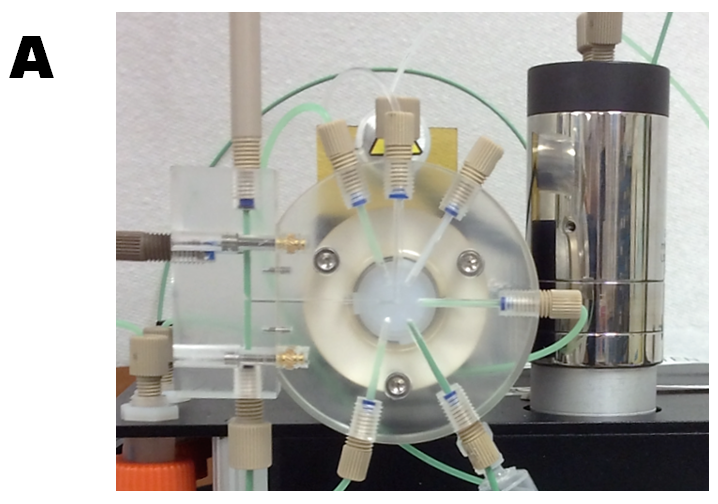

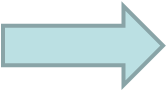

The initial work that documented feasibility of Bead Injection technique was carried out with a microSIA instrument furnished with a single syringe. However, more advanced instrumentation, the miniSIA-1 (A) and miniSIA-2 (C) instruments (Global FIA) furnished with appropriately designed microcolumn and flow cell is more suitable and convenient to use.

3.1.5.

BI in Sequential and programmable FI format

The advantage of pFI mode, compared to SI mode is, that it can process larger sample volumes and perfuse them through a renewable microcolumn (1.6mm I.D. 10mm long) sandwiched between the LOV and long light path flow cell. The target analyte accumulated on microcolumn is eluted into a flow cell by a small volume of eluent. In this way sensitivity of Fe assay was enhanced 500 times by extracting Fed(II)ferrozine complex from 2000mL of sample.